Notre gamme

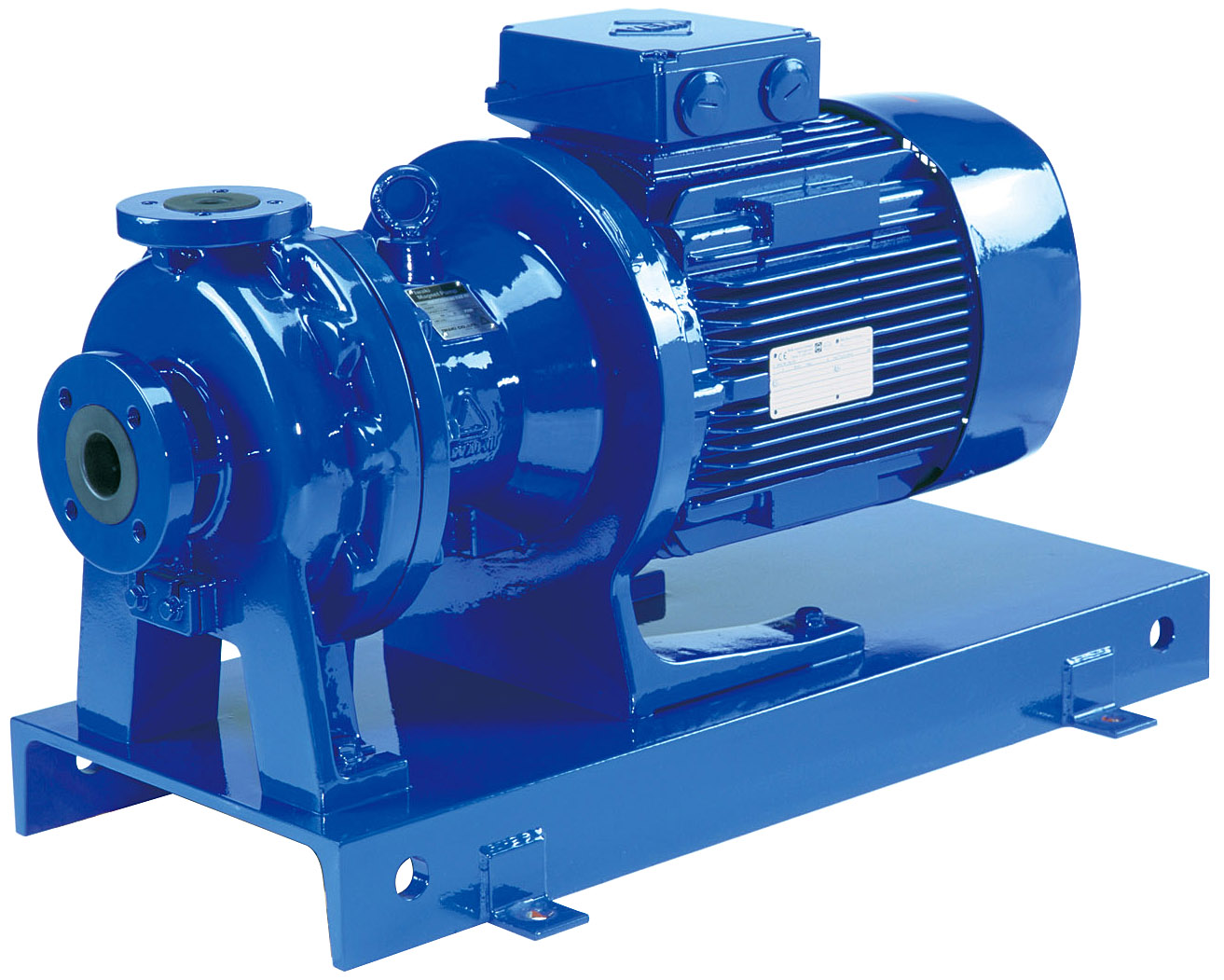

MDM series

!! NEW !! MDM-40/50-2

- High efficiency compared to similar mag-drive pumps

- New impeller design reduces the risk of cavitation

- Good resistance to abnormal operation and particles

- Easy and simple maintenance

>> High efficiency and low NPSH by optimizing design (improvement of wetted parts structure)

We pursued hydraulic efficiency by utilizing CFD. As a result, best-in-class pump efficiency has been achieved. The newly designed impeller suppresses the occurrence of cavitation. The suction characteristics have also improved.

>> Withstand pressure 1.6MPa

Adopting a rear casing cover made of CFRP achieves high pressure resistance. (Carbon fiber reinforced plastic) Pumps can handle high specific gravity liquids.

>> Improved maintainability

Addition of maintenance bolts makes disassembly and assembly safer and easier than conventional products.

Features of MDM series

>> Unique design endurable to dry running (Non contact system)

The pump design features a mechanism to withstand dry running. High magnet power of the rare earth magnets prevents the magnet capsule coming into contact with the thrust ring of the rear casing, thus preventing melting of fluororesin components due to heat generation. This greatly improves resistance against dry running in comparison with conventional magnetic drive pumps made of fluororesin. Note: Only CF type (fitted with high density carbon bearing) can cope with dry running. Dry running is not permitted in the case of KK type.

>> ETFE and PFA available in standard models

Carbon fibre reinforced ETFE (CFRETFE) and PFA linings can be supplied to meet many varying duties. PFA being a natural unfilled material generates fewer contaminants and makes it ideally suited for transfer of high purity chemicals.

>> Back pullout system

In order to facilitate inspection and maintenance, this series employs the back pullout system. This enables one to conduct inspections internally and replace parts without removing piping. The pump is designed to include safety measures that can prevent the liquid from leaking when the foot support is pulled back.

Download

- MDM25-1301-2PC-3556

- MDM25-1401-2PC-3557

- MDM25-1501-2PC-2592

- MDM25-1601-2PC-3558

- MDM25-1602-2PC-3029

- MDM25-1651-2PC-2594

- MDM25-1702-2PC-3031

- MDM25-1802-2PC-3033

- MDM25-1803-ECF-2PC-3740

- MDM25-1803-KKF-2PC-3217-1

- MDM25-1902-2PC-3035

- MDM25-1903-ECF-2PC-3741

- MDM25-1903-KKF-2PC-3395-1

- MDM25-1952-2PC-3037

- MDM25-2003-ECF-2PC-3742

- MDM25-2003-KKF-2PC-3219-1

- MDM25-2103-ECF-2PC-3743

- MDM25-2103-KKF-2PC-3220-1

- MDM25-2203-ECF-2PC-3744

- MDM25-2203-KKF-2PC-3221-1

- MDM25-2253-ECF-2PC-3745

- MDM25-2253-KKF-2PC-3396-1

- MDM32-1201-2PC-3591-1

- MDM32-1301-2PC-3592-1

- MDM32-1401-2PC-3593-1

- MDM32-1501-2PC-3594-1

- MDM32-1601-2PC-3595

- MDM32-1602-ECF-2PC-3770

- MDM32-1602-KKF-2PC-3256-2

- MDM32-1651-2PC-3596-1

- MDM32-1702-ECF-2PC-3771

- MDM32-1702-KKF-2PC-3257-2

- MDM32-1802-ECF-2PC-3772

- MDM32-1802-KKF-2PC-3258-2

- MDM32-1902-ECF-2PC-3773

- MDM32-1902-KKF-2PC-3400-2

- MDM32-2002-ECF-2PC-3774

- MDM32-2002-KKF-2PC-3260-2

- MDM32-2102-ECF-2PC-3775

- MDM32-2102-KKF-2PC-3261-2

- MDM32-2202-ECF-2PC-3776

- MDM32-2202-KKF-2PC-3262-2

- MDM32-2252-ECF-2PC-3777

- MDM32-2252-KKF-2PC-3263-2